| AQ洗涤

|

|

除油过程

|

|

喷砂

|

|

丝网印刷

|

|

|

|

|

| 喷涂

|

|

电解化学抛光

|

|

三价铬化

|

|

硬铬

|

|

|

|

|

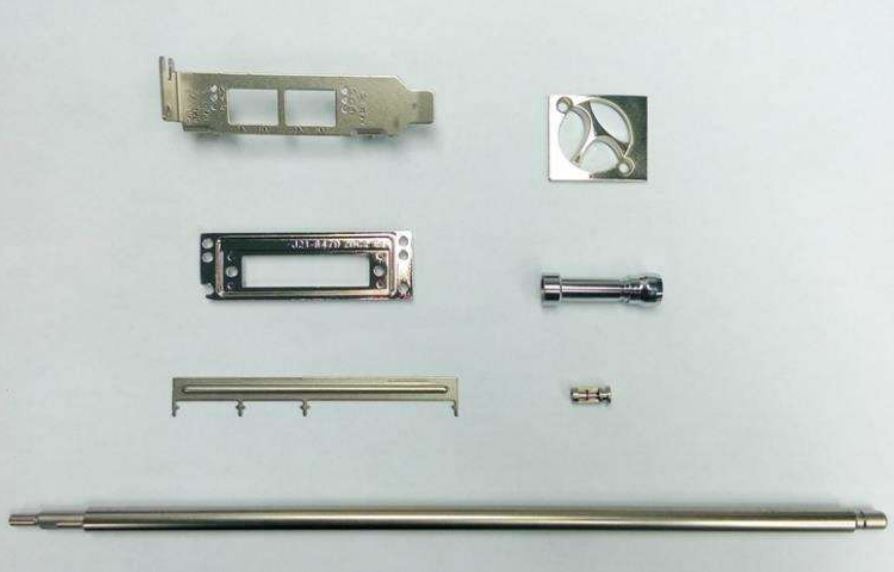

| 化学镀镍

|

|

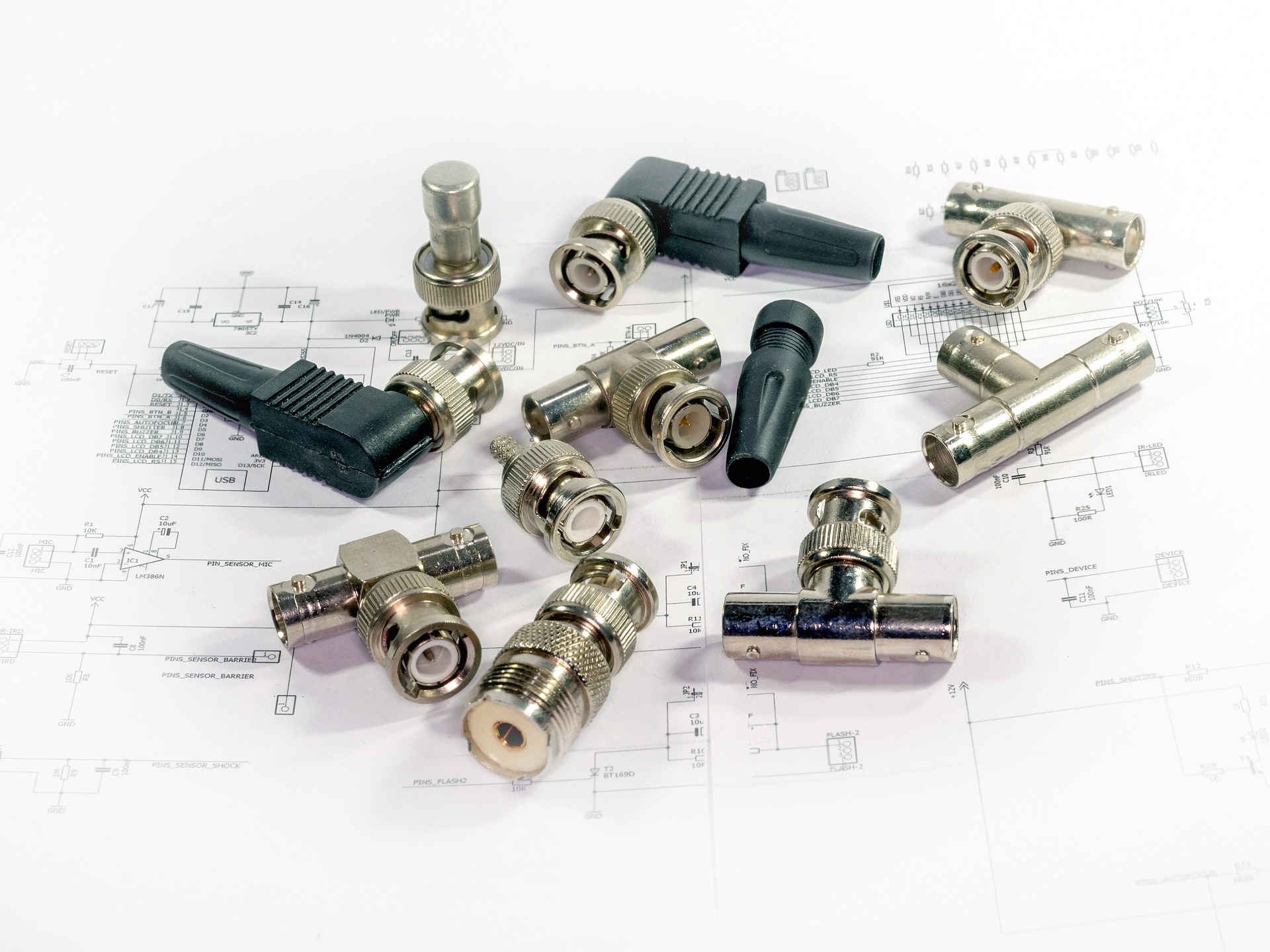

铜,镍,铬

|

|

缎面镀镍

|

|

镀锌镍

|

|

|

化学镀镍

|

|

Electroless nickel plating is an auto-catalytic reaction used to deposit a coating of nickel on a substrate. One of the advantages is that it is not necessary to pass an electric current through the solution to form a deposit. This plating technique is to prevent corrosion and wear. EN techniques can also be used to manufacture composite coatings by suspending powder in the bath.

Electroless nickel plating has other advantages versus electroplating. The process is free from flux-density and power supply issues, it provides an even deposit regardless of workpiece geometry, and with the proper pre-plate catalyst, can deposit on non-conductive surfaces. There are mainly 3 types of Electroless nickel process which is the Low-phosphorus (Low-P), Mid-phosphorus (Mid-P) & High-phosphorus (High-P).

|

|

|

|

|

|

|

铜,镍,铬

|

|

| Pending content

|

|

|

|

|

|

|

缎面镀镍

|

|

| Pending content

|

|

|

.jpg)

|

|

|

|

镀锌镍

|

|

| Pending content

|

|

|

|

|

|

|

|

| 镀锡

|

|

氨基磺酸镍电镀

|

|

电子大衣(丙烯酸树脂)

|

|

钝化

|

|

|

镀锡

|

|

| Pending content

|

|

|

|

|

|

|

氨基磺酸镍电镀

|

|

| Pending content

|

|

|

|

|

|

|

电子大衣(丙烯酸树脂)

|

|

| Pending content

|

|

|

|

|

|

|

钝化

|

|

| With the aid of chemicals, usually acid, passivation process shields the outer layer of a base material and make the surface of the material ‘passive’. In this way, the material becomes less affected by the environmental factors which often result in oxidation and leads to corrosion. The technique of passivation is mainly to preserve the appearance of metallic of metallic base material.

|

|

|

|

|

|

|

|

| 速度印刷

|

|

粉末涂料

|

|

激光印刷

|

|

特氟龙涂料

|

|

|

速度印刷

|

|

| Pending content

|

|

|

|

|

|

|

粉末涂料

|

|

| Pending content

|

|

|

|

|

|

|

激光印刷

|

|

| Pending content

|

|

|

|

|

|

|

特氟龙涂料

|

|

| Pending content

|

|

|

|

|

|

|

|

|

|

|

|

阳极电镀

|

|

| An electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodizing increases resistance to corrosion and wear, and provides better adhesion for paint primers and glues than bare metal. Anodic films can also be used for a number of cosmetic effects, either with thick porous coatings that can absorb dyes or with thin transparent coatings that add interference effects to reflected light. Anodising is one of the more environmentally friendly metal finishing processes.

|

|

|

|

|

|